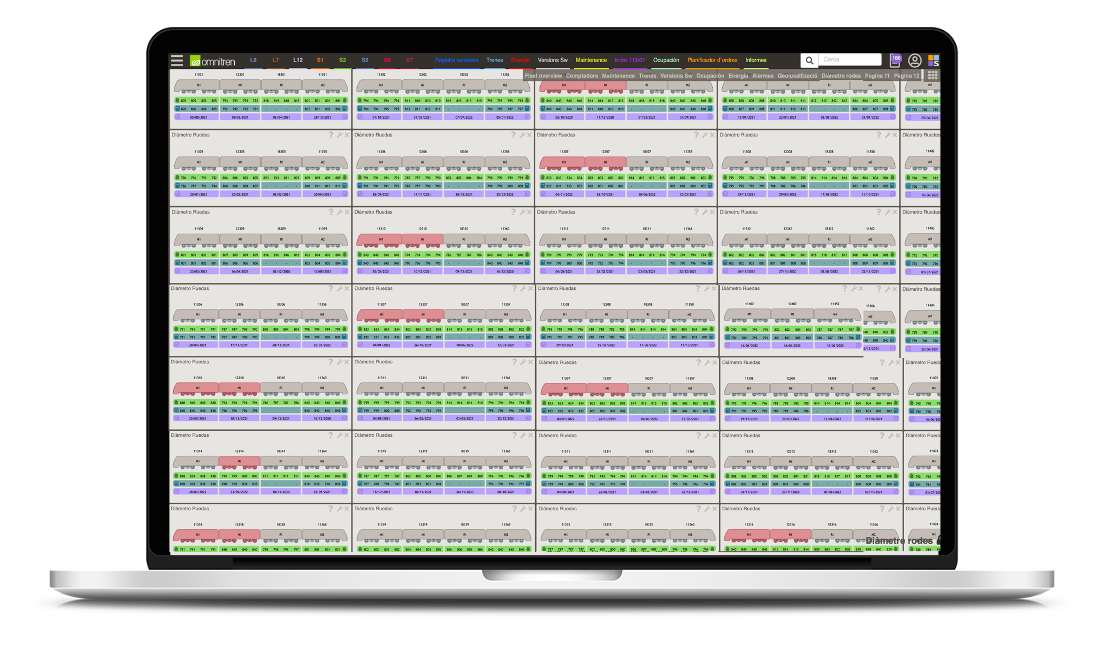

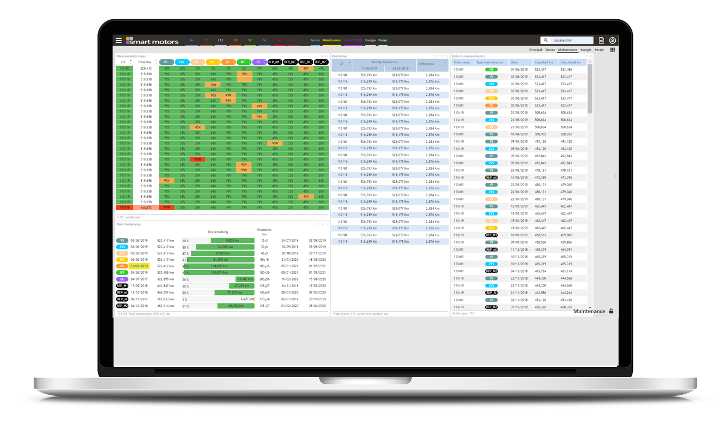

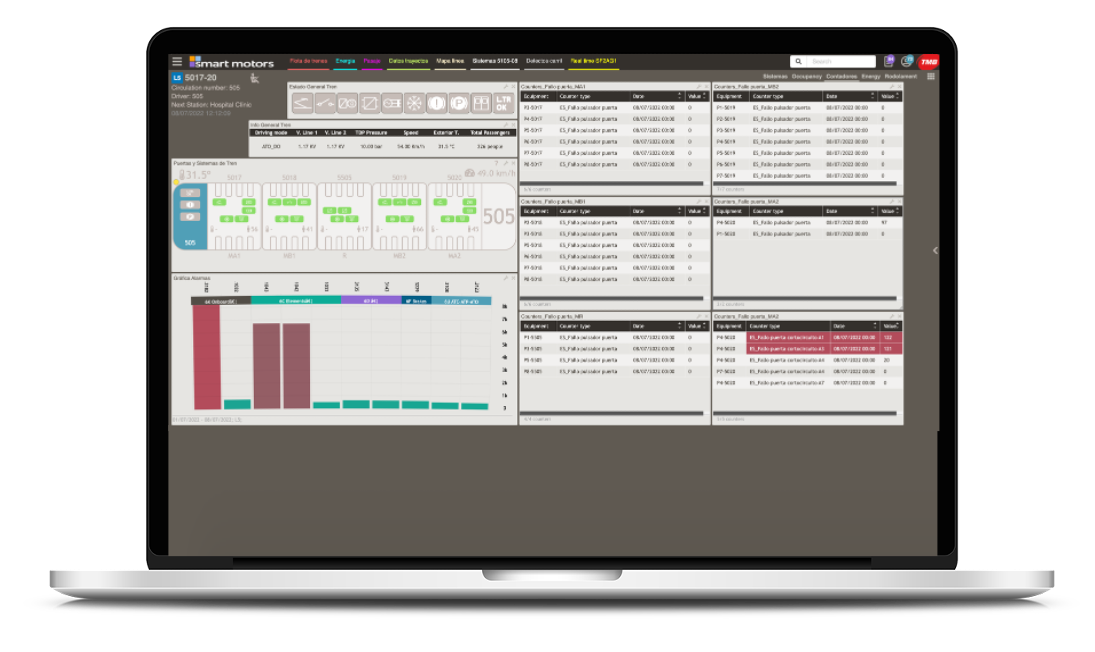

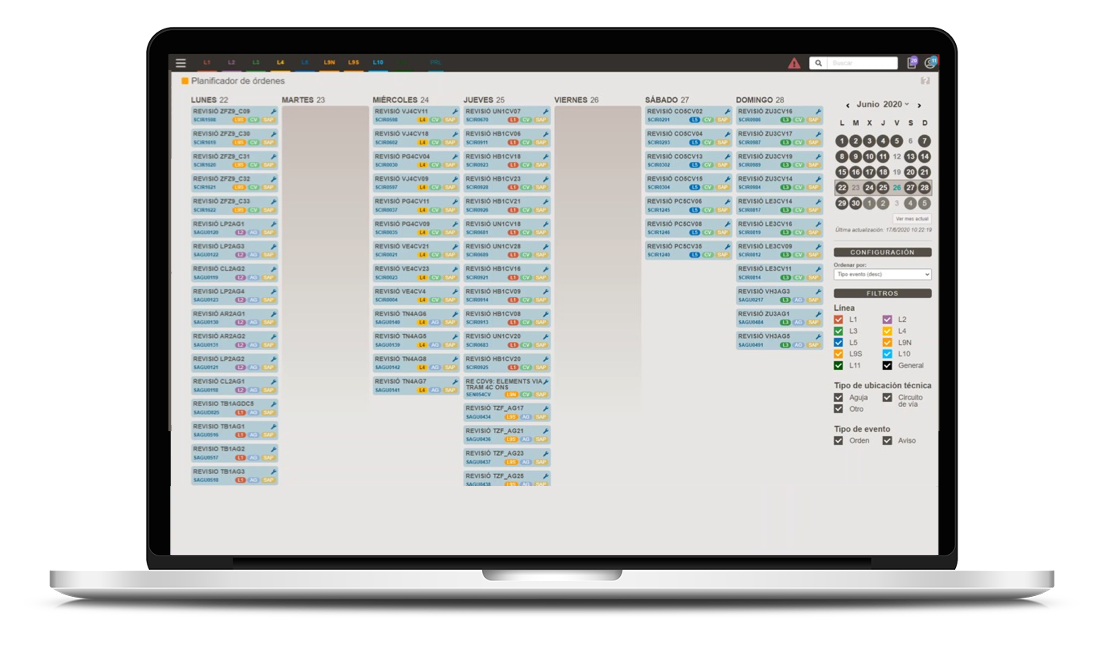

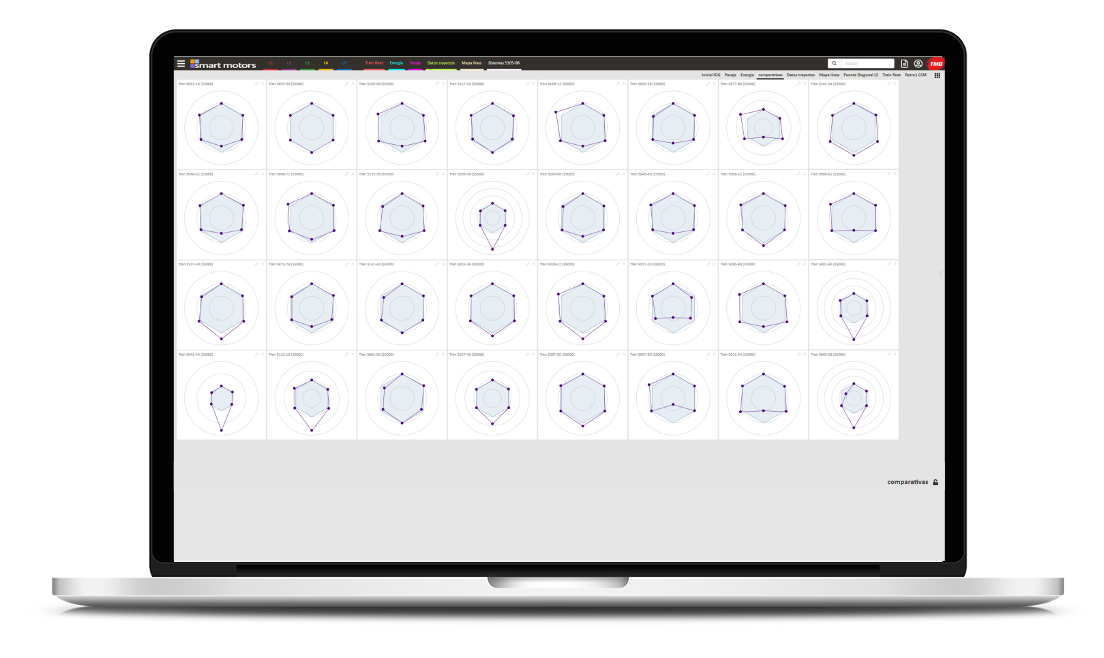

One of the most demanded applications for maintenance is the analysis of the real MTBF of train systems and sub-systems. Thanks to the platform effect that is created when the computer is loaded on the train, it is possible to count, time and trace any process that happens on the train and quantify its actual use. Based on that actual use, and not train mileage, Digital Train® applies statistical processes to operating failure rates and plans the necessary preventive activities.

Increase the availability of train subsystems based on the analysis of the average failure time and the real use.