The solution adapts to the existing assets. We can monitor the track with on board devices or on track.

Installation satisfies all railway certifications. The system is modular, compact, hot swappable and calibration is done remotely.

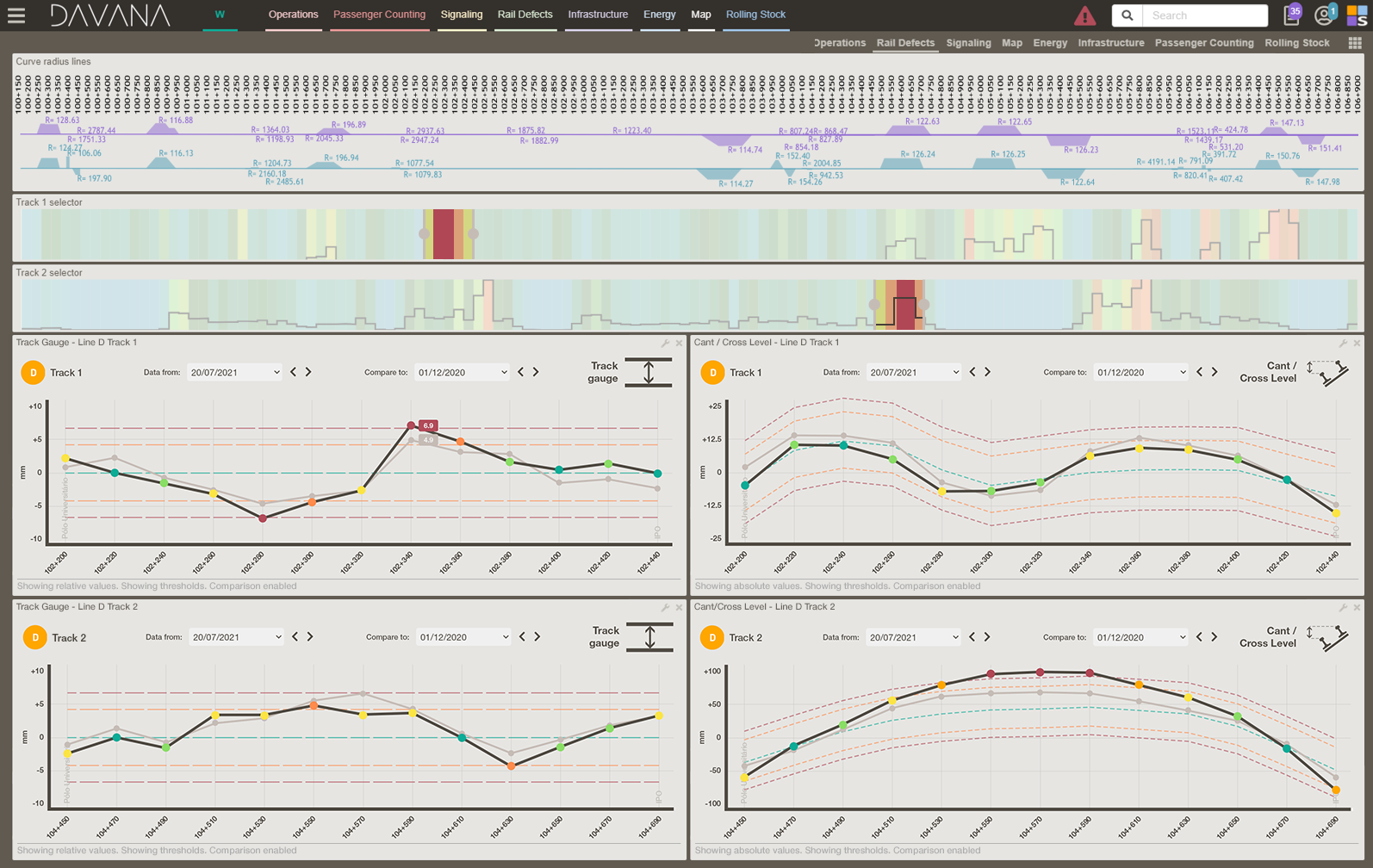

DAVANA integrates all monitored assets, optimizes maintenance and reduces infrastructure costs.

By monitoring assets on a continuous basis, the likelihood of incidents is reduced and responsiveness is increased.

The tool set allows the track maintainer to visualize the lane status and to assess qualitatively and quantitatively the degree of defects that each section of track presents.

The aim of this functionality is to offer the maintainer the possibility of performing a maintenance based on the real condition of the lane, defining operating limits, alarms, planning times, etc.

The solution allows to detect irregularities on railtrack and quickly react to failures. Using a kinematic approach, the computer vision system and inertial sensors map the entire network through which the equipped trains pass. The best alternative solution to traditional auscultation. No more heavy trolleys and expensive laboratory vehicles. The hardware solution us powered by Virtualmech.

Together with our partner SKF, we've deleveloped a solution to

analyse defects along the network by only monitoring one train. Using the SKF's Multilog IMx installed in the bogies, the system then can relay performance data to DAVANA which process it, and in the case of anomalies, alarms are sent to the maintenance team.

As a complementary solution we offer Blacknest SURFACE, a sensor adapted to the train's circulation needs and which requires very occasional maintenance, making its installation technically and economically feasible.

The compact IoT sensor was created with the aim of continuously monitoring the temperature of the rail, as well as the tilting and vibrations, with a device that can be easily installed. The data collected and the AI analysis are helping to prevent railtrack breaks. It is installed directly on the rail with magnets. Integrated LTE-M1 communication guarantees low data consumption and does not require repeaters to be placed on the track.

Blacknest SURFACE is particularly appropriate for sensitive areas, such as sidings, problematic joints, or areas with significant temperature gradients.

(+34) 938 023 379

Headquarters: Barcelona, Spain

Plaça de la Tolerància, 17

08027 Barcelona (SPAIN)