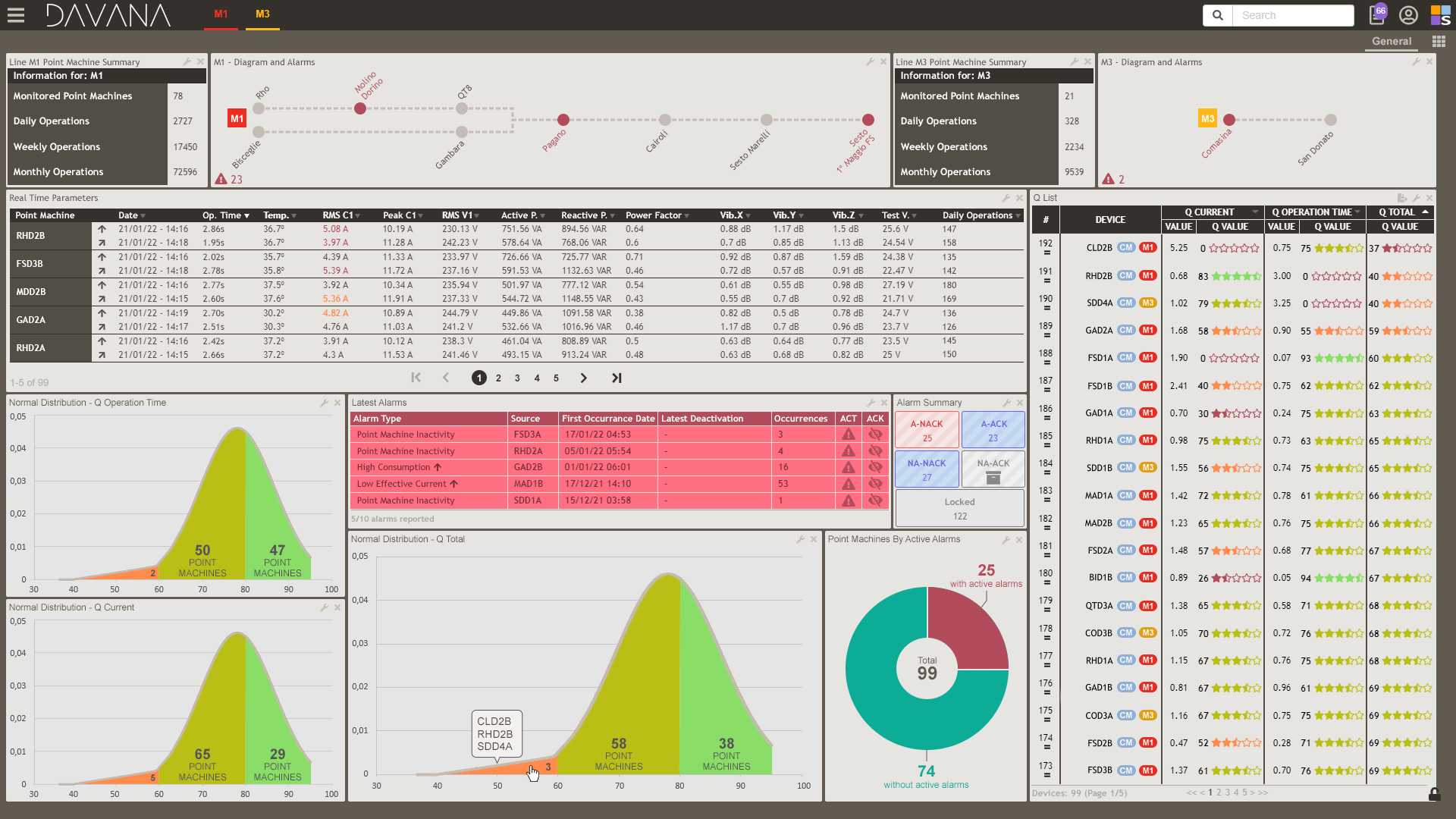

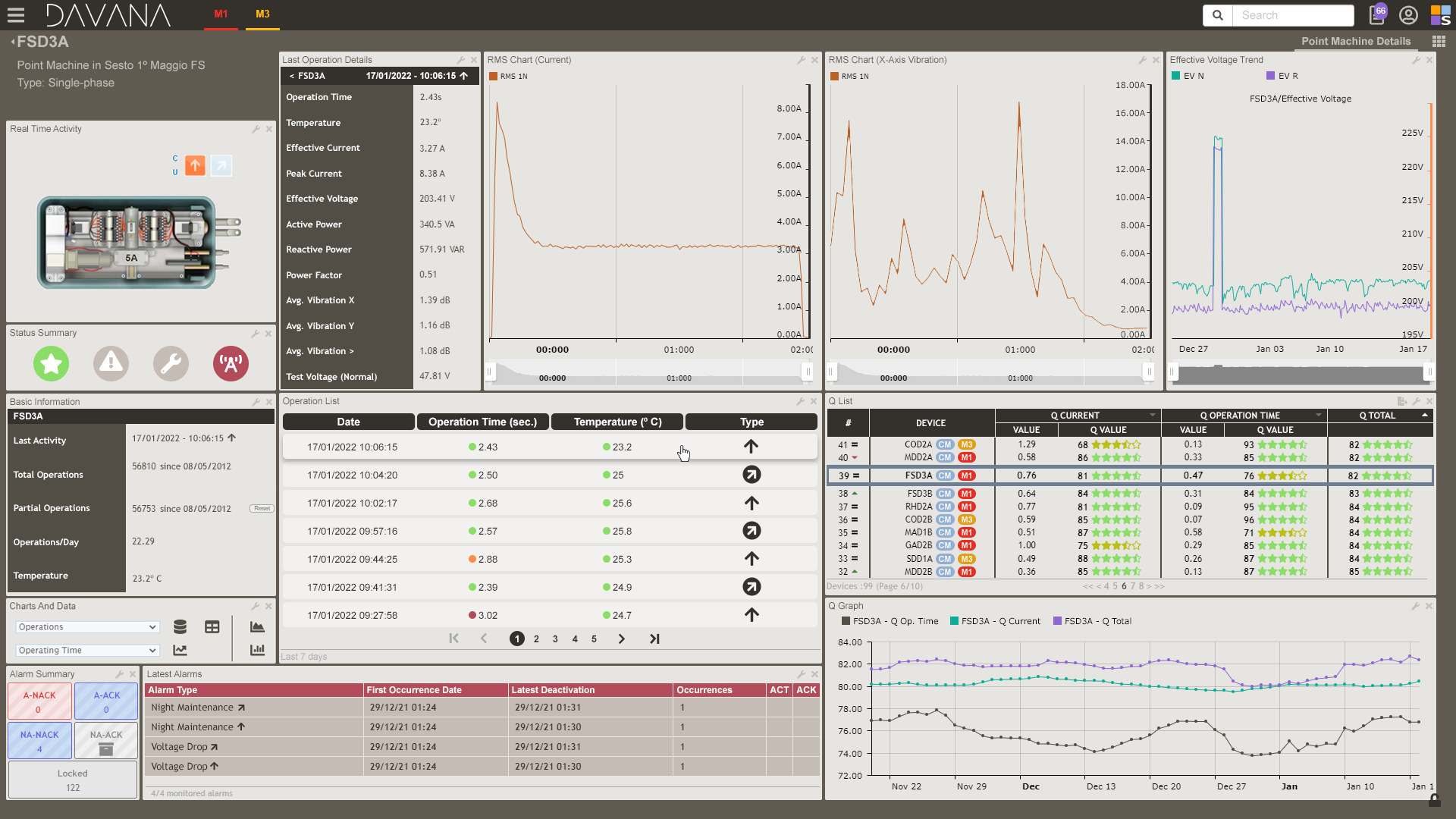

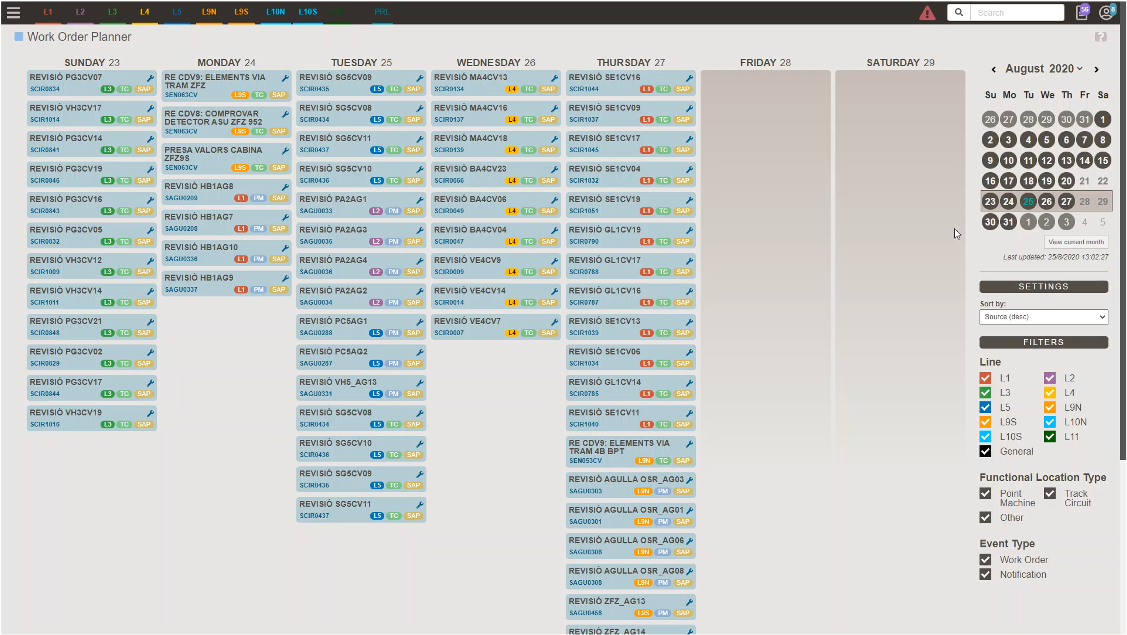

Traditional point machine monitoring is being reinvented to meet today’s stringent safety requirements and quality standards. DAVANA® condition monitoring tools ensure a fast return on investment thanks to breakdown prevention and optimization of the maintenance.

Thanks to our high-performance sensors, suitable for different technologies, use the data collected to predict breakdowns and foster a more efficient maintenance plan.

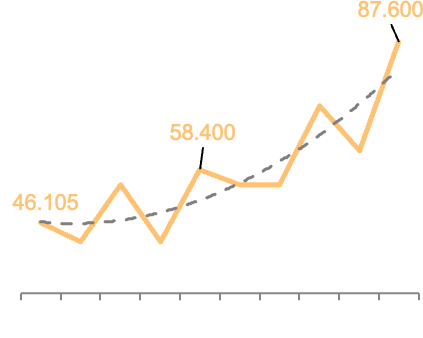

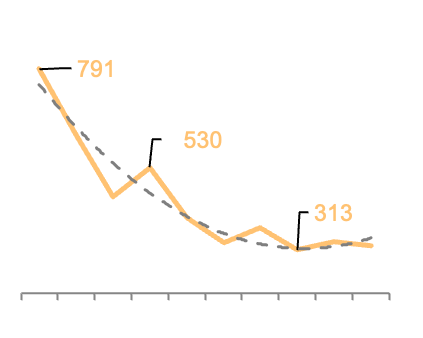

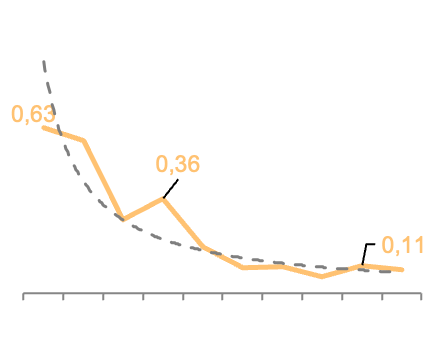

Results based on more than 1000 installations

With more than 1000 point machines monitored around the world, including different electrical and mechanical features, smart motors® has achieved a milestone on:

Reliability MTBF (hours)

96x55.png?width=96&height=55&name=x2%20(2)96x55.png)

Stop time per Machine (minutes)

96x56.png?width=96&height=56&name=x7%20(1)96x56.png)

Maintenance activity cost (€ per asset)

96x55.png?width=96&height=55&name=x3%20(2)96x55.png)

Customize the platform and get further benefits:

The best monitoring devices according to your needs

DAEN

Data logger that monitors from electrical, mechanical and environmental parameters installed inside the point machines with high performance and high precision thanks to its multithread capability. It continuously records up to 20 parameters (24/7)

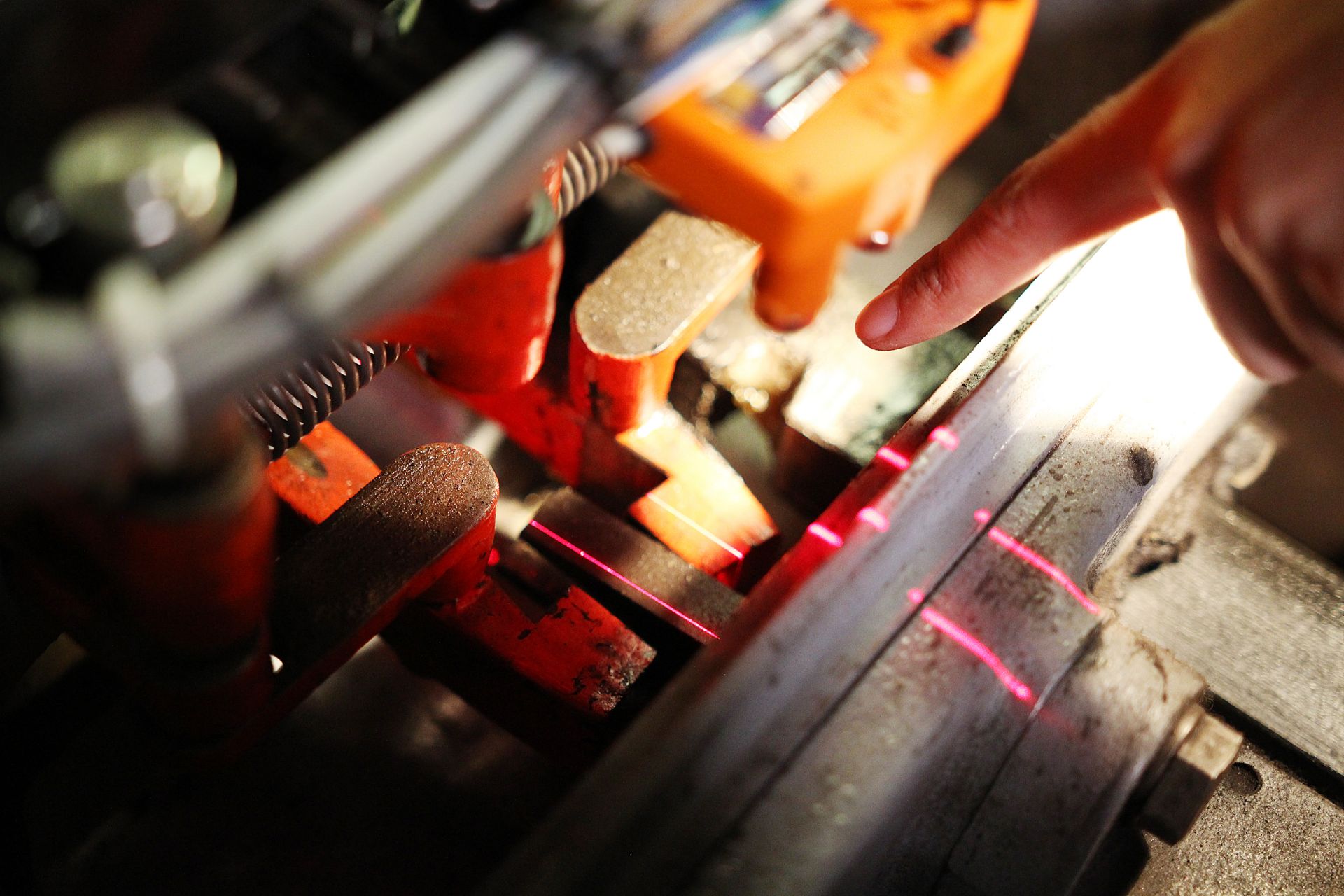

CDX

Artificial vision equipment that measures the clearances of the detection mechanism, exclusively in point machines with control bars and detection modules. It is placed inside the protection shield of the Point Machine, above the lock. It uses structured light to measure a laser projection on the control gap with a precision of 0.1 mm.

DAEN Lite

Data logger that monitors electrical parameters with high performance and high precision thanks to its multithread capability. It's indicated for point machines with less impact on the service or where is not possible to install a DAEN.

DAEN Lite IoT

Data Lite provided with IoT capabilities. Indicated for isolated point machines or if there is no possibility of installing the rest of the system architecture of the standard version in the signaling room.

Blacknest surface

Sensor installed on the track, in the vicinity of the turnout, and that can capture the values of temperature, humidity, vibration and inclination. They are used in combination with DAEN Lite, to collect environmental and mechanical data.

(+34) 938 023 379

Headquarters: Barcelona, Spain

Plaça de la Tolerància, 17

08027 Barcelona (SPAIN)