Train tracks have a bad habit of warping with temperature changes. The ground also dries and shrinks, causing uneven surfaces. Summer is a real problem for the train tracks, just like in strong winter, when the rails get shorter and cool. All these things cause delays.

Is it posible to know the tracks condition? How can we ensure the availability of track along the kilometers of railway networks?

Together with Virtualmech we offer a solution to analyse defects along the network by only monitoring one train.

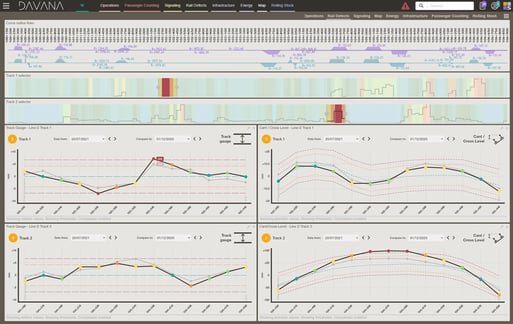

The on board system performs on real time geometry measurements of track gauge, vertical profile, alignment, cant and twist. The solution allows to detect irregularities on railtrack and quickly react to failures. Using a kinematic approach, the computer vision system and inertial sensors map the entire network through which the equipped trains pass.

The tool set allows the track maintainer to visualize the lane status and to assess qualitatively and quantitatively the degree of defects that each section of track presents.

The objective of this functionality is to offer the maintainer the possibility of performing a maintenance based on the real condition of the lane, defining operating limits, alarms, planning times, etc. In a scenario in which the maintenance of the tracks is costly and complex, this functionality monitors the condition of the tracks for condition-based maintenance and anomaly detection.

The implementation of the track defect measurement system is feasible in any type of train and completely transparent to it, it works autonomously and only requires a feeding point. All collected information is sent directly to DAVANA’s server and visualized as follows:

More solutions can be added to the most critical points of the network. Blacknest, the IoT sensors line of smart motors, can be attached to gather more information on condition.

Blacknest SURFACE is a compact IoT sensor that gives answers to the uncertainty generated by the most problematic rail sections on tracks. It monitors the temperature, vibrations and tilting of the tracks for condition-based maintenance and anomaly detection. The data collected and the AI analysis are helping to prevent railtrack breaks.

Track maintenance is very expensive and time-consuming. Equip the network with Blacknest is cost-effective and provides valuable status information to streamline the cost of infrastructure maintenance.